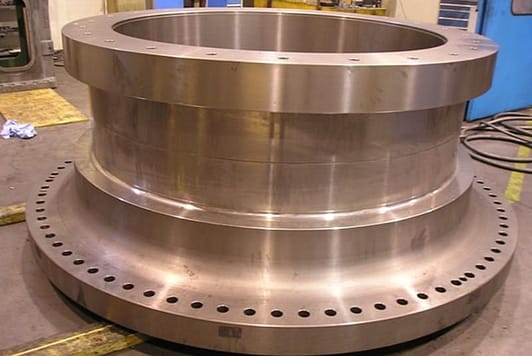

Ball Mill Hollow Shaft

Product Name: Ball mill hollow shaft

Application: Ball mill, cement machinery Industry: cement, metallurgy, building materials industries

industries

Material: Cast steel ; ZG230-450; Carbon steel, alloy steel

Dimensions: According to drawings

MOQ: 1 Metric Ton/Metric Tons hollow linear shaft MOQ is just 1MT

Price: Competitive price

Whether can be customized: Customized

Brand Name: SYMMEN

Contact us for more information on how this product can help you with your unique requirements.

Ball mill hollow shaft is a key member of cement machinery, is a special type of steel castings, its whole weight is mainly played supporting, ligation of the cylinder, and is the material out of the channel, while working to bear the main shaft diameter the bending force, the cylinder is subjected to shear forces.

Side dish fillet root ball is hollow shaft stress concentration at the time of casting parts prone to blisters, pores and microcracks defects.

In order to solve the problem of troubled companies for many years, our company casting process simulation technology is introduced, and the ball mill hollow shaft casting process improvements, basically eliminating trachoma and porosity defects journal portion, so that the quality of the hollow shaft on a a new level.

Production Process

Why choose us?

- Our company using a unique heat treatment technology, so that the hollow shaft improved hardness, impact resistance is enhanced;

- Our company production of hollow shaft made of high strength steel casting, casting in the early stage of professional engineers, steel mill also for the operating characteristics of the process structure of the hollow shaft has been optimized greatly protect the long member stability over time under the operation, to extend the service life of components;

- Our company has a solid cast steel castings production strength, can hollow shaft and other components for high-volume manufacturing, molding cycle is short, large output.